- troubleshooting of electrical system

- troubleshooting of hydraulic system

- troubleshooting of mechanical systems

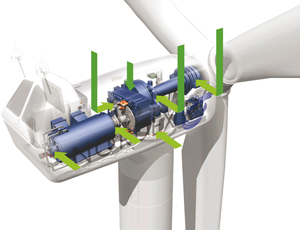

Fault Diagnosis of Wind Turbines

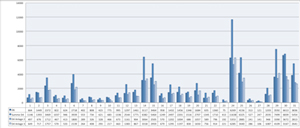

Remote Monitoring of Wind Turbines of various WEC Manufacturers per Remote Control program

- provision of remote monitoring 24 hrs / 7 days

- analysis of data provided by wind turbine

- tabular analysis incl graphs

- qualified technical support by service technicians for Operators

Dismantling and reassembly of major components

dismantling and reassembly of wind turbines (repowering and re-commissioning)

dismantling and reassembly of wind turbines (repowering and re-commissioning)- dismantling and reassembly of rotors including component sales and replacement

- dismantling and reassembly of generators and gearboxes including component sales and replacement

- planning, implementation and monitoring of projects (supervisor)

Visual Inspection

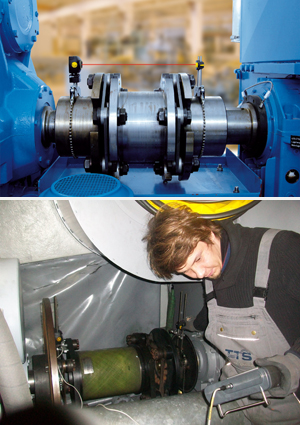

gearbox and generator inspection per video endoscope

gearbox and generator inspection per video endoscope- rotor blades and tower (inside and outside as far as accessible)

- provision of inspection reports

- detailed photo documentation

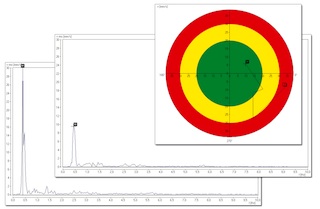

Balancing of wind turbines (Field balancing)

- determination and documentation of the vibrational condition of the wind turbine (rotor) before and after balancing

- record existing values and targeted values

- use of state-of-the-art balancing technology in cooperation with a measuring technology manufacturer

- determination of aerodynamic imbalance (for more information, see “blade angle check”)

- determination of mass imbalance and evaluation of imbalance according to DIN ISO 1940

- documentation of detected imbalance and subsequent balancing

- photo documentation (graphical representation)

- certified specialists (ISO 18436-2)

- Service: measuring, analyzing, eliminating and checking

Blade angle check

- photographic inspection of the blade angle

We are currently working on a new development for laser-optimized blade angle testing and for determining the aerodynamic imbalance.

Portable Vibration Measurements including Expert Analysis

- drivetrain vibration measurements and evaluation (mobile, online and offline) based on VDI 3834 in accordance with ISO 10816-21

- differing Turbines have have different points of measurement – X,Y & Z (horizontal, vertical and axial)

- record of measurement reports with analysis results and expert recommendations

- further repeated measurements and comparison with previous results (trend)

- certified specialists (ISO 18436-2)

Copyright 2022 Trainings Transfers Services GmbH

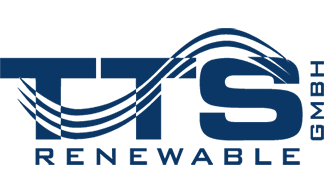

laser-based verification existing alignment

laser-based verification existing alignment